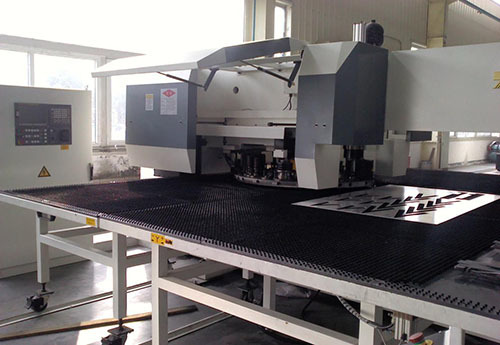

The machining center sheet workshop is composed of sheet production lines, which are responsible for the processing and production of aluminum plates, composite plates and steel plates. The production line mainly includes shearing machine, bending machine, laser cutting machine, plasma cutting machine, CNC punching machine, slotting machine, slotting machine, argon arc welding machine, etc. The equipment is complete, and the supporting capacity is strong. The annual sheet production capacity reaches 60 Above 10,000 square meters, it can be accurate for various types of plates according to the needs of the project. Precision cutting, grooving, bending and welding. It has the characteristics of high processing accuracy, stable quality, good appearance effect and high production efficiency.

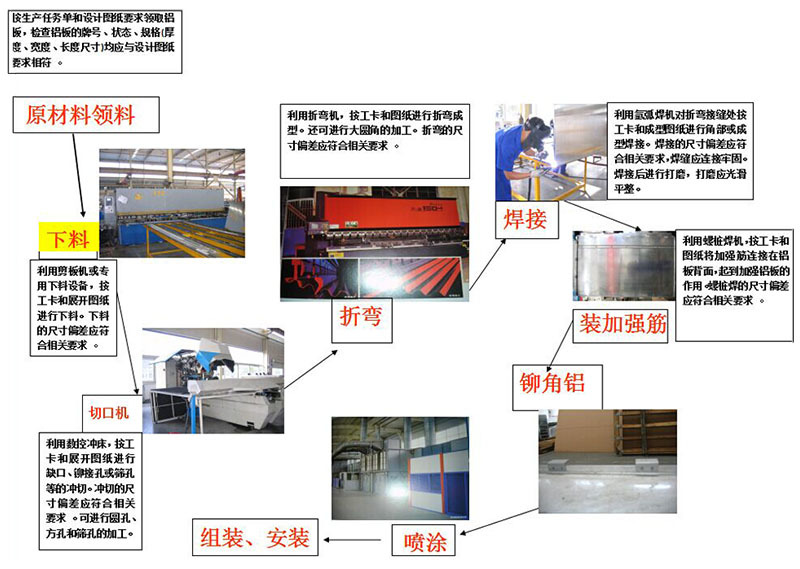

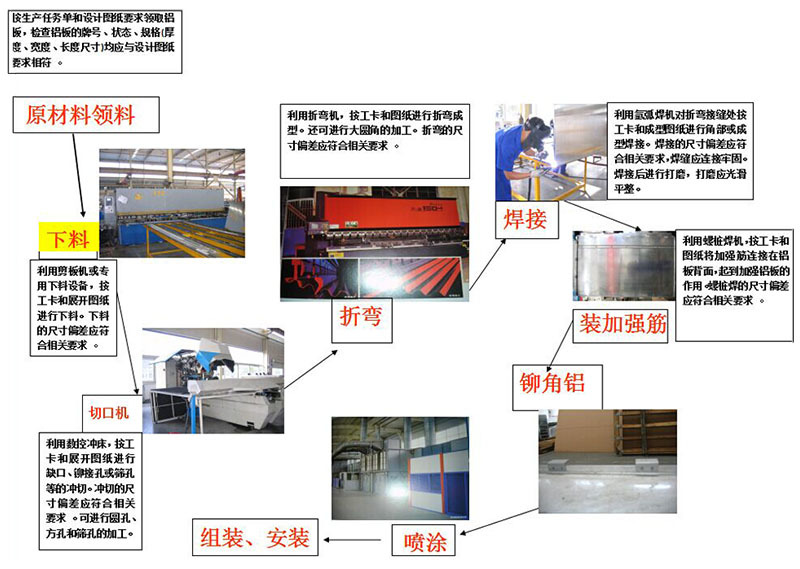

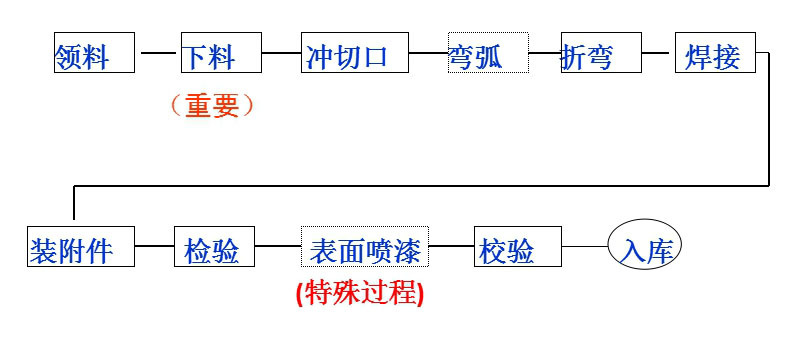

Single-layer aluminum plate manufacturing process flow chart

Single layer aluminum plate manufacturing process flow chart

CNC Fine Plasma Cutting Machine: Magician

● Place of origin: Wuhan <Faripinade>

● Cutting material: stainless steel, carbon steel, aluminum plate

● Effective cutting width is 3000mm, gauge is 4000mm (subject to final design)

● Effective cutting length is 12000mm, rail length is 15000mm

● Plasma cutting thickness 1-32mm, cutting torch lifting stroke 200mm

● The idle speed is 24000mm / min, the cutting verticality is ± 1.5 degrees

● Cutting speed is 0-12000mm / min, positioning accuracy ± 0.15mm / full length

● Repeat accuracy is ± 0.15mm / full length, the diagonal deviation is in the range of 4m × 10m, and the diagonal error is less than ± 0.5mm

● straightness of the machine? ? ± 0.3mm / within the effective cutting length of the equipment, horizontal walking straightness ± 0.2mm / within the effective cutting width of the equipment

● Plasma height control accuracy? ± 0.2mm (arc voltage control), cutting section roughness Ra12.5

CF corner forming machine:

● Place of Origin: Austria (ACF)

● The only domestic and international leading corner forming technology

● Seamless stretch forming without welding, excellent waterproof performance

Stainless steel slotting machine V-6012:

● Place of Origin: Japan <Amada Corporation>

● Planing grooves for flat plates such as stainless steel, aluminum, honeycomb, and wooden boards

Slot depth positioning accuracy ± 0.05mm / m

● Maximum processing length 6m

● Maximum automatic feed speed 25m / min

● After the slot is bent, the edges and corners can be clearly distinguished, which brings a strong visual impact.

● Can effectively solve the problems that cannot be directly bent

● Brings convenience for subsequent processing, for example: after forming some parts, it is not possible to perform spray coating processing due to the influence of the processing size of subsequent spraying equipment.

● Slotting, pre-bending, and forming after spraying

● For relatively thick workpieces, cracks are easy to occur when using conventional bending, and can be avoided after grooving.

CNC Bending Machine FBD1540:

● Place of Origin: Japan <Amada Corporation>

● Seven-axis control system is used for bending and bending of plates

The maximum bending pressure is 150 tons

The maximum bending length is 4000mm

● Processing accuracy is ± 0.15 °

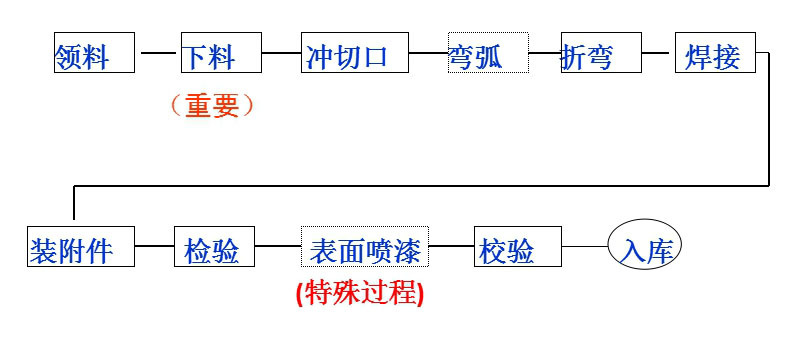

Sheet metal cutting center 212RH:

● Place of Origin: Harco, Belgium (HACO)

● Automatic mold change, spindle mold can be rotated arbitrarily, and the length of secondary positioning can be unlimited

Maximum punching force 30 tons / 20 tons

● The maximum size of the plate is 2000mm (single positioning), width 1500mm

Mould library 20/12

● Maximum sheet thickness: 10mm

● Maximum punching area: 880mm2.

QC12K-6 × 4 Shearing machine

● Place of Origin: Domestic

● For sheet blanking

Maximum Shearing Length 4m

● Maximum Shear Plate Thickness 6mm

● Positioning accuracy ± 0.2mm

CNC punch is a very fast and effective punching equipment for aluminum plate notches, round holes, arc edges and other processing. Our company's Jinfangyuan CNC punch is a fast punch CNC punch, the maximum punching width is 1500mm, and the maximum punching thickness is 6mm. Maximum die diameter? 88.9mm, repeat positioning accuracy of 0.1mm, clamp width of 300mm.

The slotting machine equipment is mainly used for stainless steel plate processing and aluminum plate processing. The maximum length of the aluminum plate can be 6000mm and the width is 1500mm.

A gas-supply screw pile welding unit consisting of 10 screw pile welders, with a special welding tool for the welding torch, with stable air pressure and reliable welding quality.