Spraying production line

The spraying workshop of the machining center is composed of a spraying production line. The spraying production line is responsible for pre-treatment and spraying of sheet and aluminum profiles to play a role in surface decoration and anticorrosion. At present, our company's fluorocarbon spraying production line is constructed by Shenzhen Kaiyuanda Equipment Co., Ltd. The entire spraying equipment is the most advanced in China. The spray gun is a magnetically levitated rotary cup spray gun provided by the French company Sames. The speed can reach 80,000 rpm / MIN. (At present this technology is only available in the automotive industry) The main advantages are: environmental protection, stability, high coating utilization, high product quality and other characteristics. The annual production capacity can reach 1 million square meters.

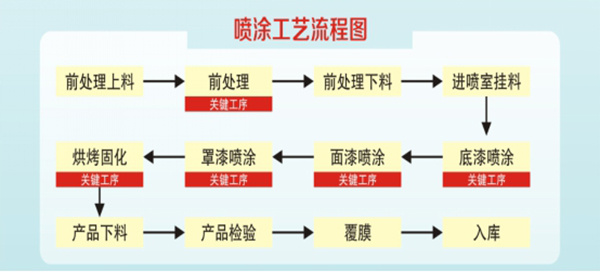

The entire process of spraying has set up five key processes: pretreatment, primer spraying, topcoat spraying, varnish spraying, and baking curing.

Fluorocarbon spraying production line

● Introduce the world-class fully automatic pretreatment and fluorocarbon spraying production line

● The pre-treatment is based on the aluminum profile processing technology of German HENKEL company, and the standard nine-station processing system;

A set of 50 tons of deionized water production equipment;

● A set of electrostatic dust removal device;

● Equipped with equipment according to the standard three-coat and one-bake process, with six large automatic spray booths;

● The spray booth realizes automatic ventilation, temperature control and automatic air filtration

● Ten sets of French SAMES company PPH308 electrostatic high voltage magnetic rotary screw cup spray gun (0-101KV) and support system;

Four sets of Japanese RANSBURG company, REA-Ⅲ manual spray gun;

● A set of automatic workpiece identification system (can realize profiling);

● A set of 45M long and 1.5M wide channel curing furnace, self-adjusting temperature between 25-280 degrees;

A harmful gas reburning facility to ensure that the environmental quality meets national requirements;

● A set of automatic sewage treatment equipment that meets the national requirements.

Color matching system for fluorocarbon spraying production line

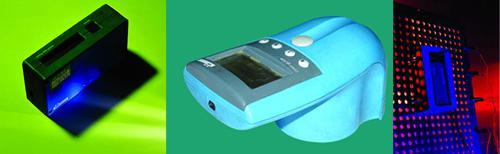

● In order to meet customers' needs for color diversity in a timely manner, our company has an advanced color matching system, which mainly includes:

● PPG-Macbeth COLOR EYE 2145 color matching software and color analyzer

● SHEEN CAC120 standard light source box (for color matching and inspection)

● Singapore WTC oven (automatic ventilation, 0-300 ℃)

● 5g single head balance

● One small spray booth for laboratory

Color matching system for fluorocarbon spraying production line

● In order to meet customers' needs for color diversity in a timely manner, our company has an advanced color matching system, which mainly includes:

● PPG-Macbeth COLOR EYE 2145 color matching software and color analyzer

● SHEEN CAC120 standard light source box (for color matching and inspection)

● Singapore WTC oven (automatic ventilation, 0-300 ℃)

● 5g single head balance

● One small spray booth for laboratory