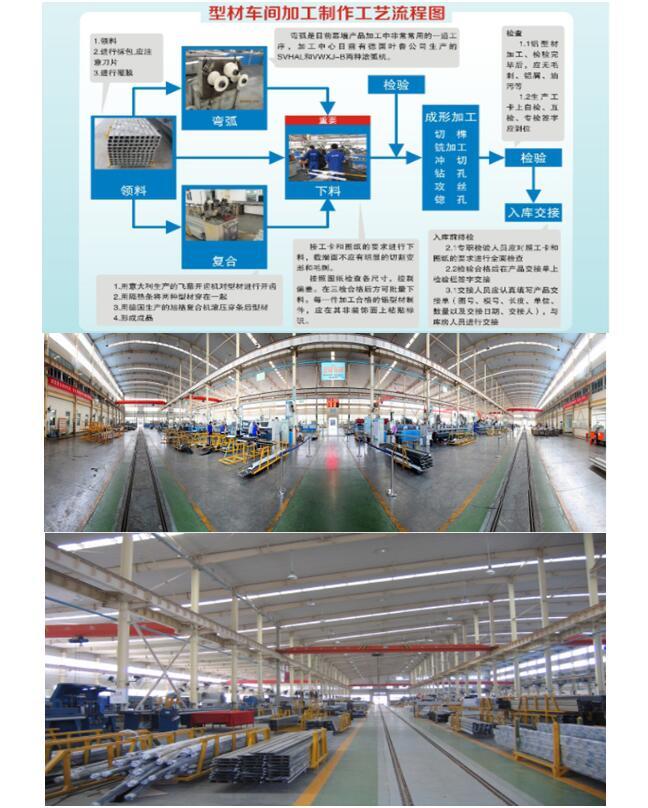

Profile production line

The profile production line of the machining center profile workshop is responsible for the processing of the main and auxiliary aluminum profiles of the curtain wall and the profiles of the mounting system.

All the profile equipment is imported from Germany and Italy, including double-head miter cutting machine DG244, multi-function profile machining center SBZ130, end cutting machine KS107 / 30, end milling machine AF223, three-dimensional miter cutting machine AKS134, thermal insulation cold bridge section Gear machines, heat-insulating cold-bridge profile laminating machines and other world-class profile processing equipment have the characteristics of high processing accuracy, stable quality, and good appearance of processed products, and can meet the different processing needs of various types of curtain walls and roof systems. The composite profiles are firmly connected, safe and reliable, and can meet the composite processing of various types of thermal insulation cold bridge profiles for curtain walls, doors and windows.

Profile machining center SBZ 130--5 axis CNC machining center

● Place of Origin: Germany <Ylumate>

● Full computer control, three-axis linkage, drilling and milling from five directions

● Maximum processing length 9m, processing length 7080mm, width 480mm, height 325mm

● Accuracy ± 0.1mm / 1000mm, diameter of milling cutter 80mm, suitable for cutting and cutting tenon, can meet the needs of high-level curtain wall processing

Positioning accuracy is 0.1mm / m

The fastest running speed is 45m / min

● Characteristics: high processing efficiency, good precision and strong repeatability

DG142 + E355 from Yale, Germany --- double head saw.

● Feeding of main functional profiles, processing accuracy ± 0.1mm / 1000mm

● Features: high processing efficiency and good accuracy

Domestic--6 head drilling machine

● Drilling of main profile, multi-head or single-head milling

Profile processing SBZ 150

SBZ150 is a drilling and milling machine with 17 types of tools that can be replaced in Germany. It can process six sides of aluminum profiles, and can perform five types of processing: milling, drilling, tapping, countersinking and cutting. The axis and C-axis rotate, with adjustable and movable clamping system. Processing accuracy is ± 0.1mm / M, X axis 9000mm; Y axis 1000mm; Z axis 650mm; A axis: 0/45/90 indexing; C axis: 90/45/0 / -45 / -90 / -135 / -180; 90/180; saw blade diameter: up to 300mm

● The biggest machining advantage: It can process the elements in any orientation above the plane.

Profile compounding --- Insulation cold bridge profile compounding machine

● SCHUCO

● It is used for automatic threading and compounding of thermal insulation cold bridge profiles.

● Equipped with special testing equipment.

● compound speed 60 m / min

CNC milling machine for profile processing KELT 6500

● Place of Origin: Italy <Emmegi>

● Full computer control, three-axis linkage, drilling and milling from five directions

● The maximum processing length is 6500mm, which can meet the processing requirements of high floor curtain wall

Positioning accuracy is 0.1mm / M

● The fastest running speed is 80M / Min

● Characteristics: High processing efficiency, good precision and strong repeatability.

Single head drilling machine from Yale, Germany--SA103 / 35, single head saw (angle code saw)

● Main function, automatic corner cutting,

● Processing range: 10mm to 300mm